Watch A Demo

Demo On-Demand

Explore how Novarc’s welding solutions perform in real-world applications with our on-demand demos, featuring carbon steel, stainless steel, TIPTIG, and fully automated pipe welding with NovEye Autonomy. Each demo provides a detailed look at how our technology handles various materials and welding conditions, ensuring efficiency and precision.

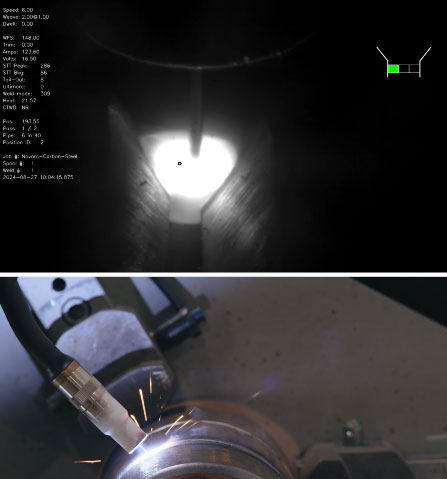

Carbon Steel On-Demand Demo

Watch Demo

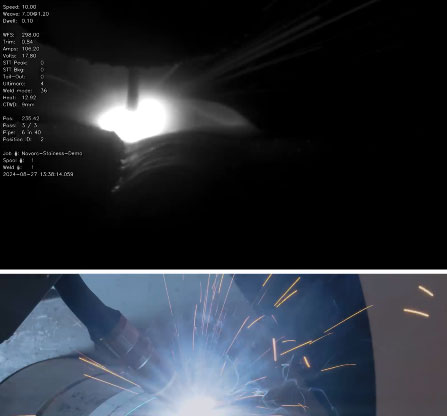

Stainless Steel On-Demand Demo

Watch Demo

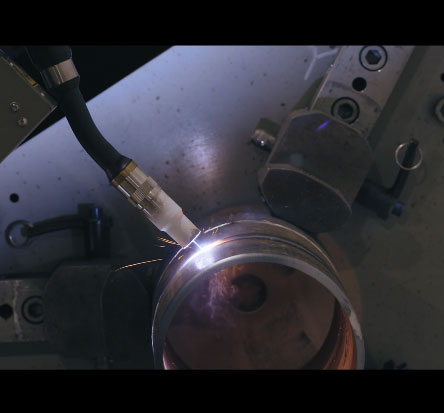

Fully Automated Pipe Welding On-Demand Demo

Watch Demo

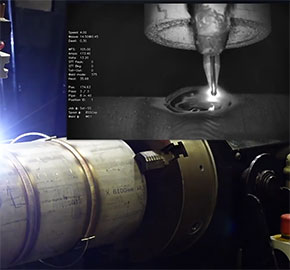

SWR-TIPTIG On-Demand Demo

Watch Demo

Customer Success

See What Our Customers Achieve

"Remarkably, the SWR has proven to be equivalent to having four to six skilled welders on average for our operations."

Trident Process Systems

"The cost of weld repairs is typically between $800.-$1,000 per test, and with Novarc we’ve achieved a 0% failure rate."

Metropolitan Mechanical Contractors, Inc.

"Novarc did some testing for us and we fell in love.The first project we did we cut off 4.5 man weeks of shop welding, so we saved around $114,000 on that project, and it made us competitive and added value to the end user."

Western Allied Mechanical"The quality side of it is definitely the data aspect; the ability to tie in the weld data and video logs with our BIM information was a very big bonus."

Wade Eno|CEO of RoboFab

"We have shown more than half a dozen of our customers around the machine. It’s a powerful message to our clients that we are investing in a piece of technology that’s going to make the work we do for them less expensive, higher quality, and take fewer hours."

Seaspan's Vancouver Drydock Company Ltd."We looked at a few other options when looking for welding solutions. The edge that Novarc has is the footprint of the equipment, we have a lot more flexibility with the SWR ... The other reason why we went with Novarc is that Novarc showed up here with what we call a “fresh air”. A new product that is really dedicated to improving pipe welding."

Ganotec|Muga Fab

"We knew autonomy was a big deal when one of our operators forgot he was welding and walked away from the machine. It's been fantastic to collaborate with NovARC on another industry-defining evolution."

Pitt Meadows Plumbing & Mechanical Systems Ltd.

"We've achieved a 400-500% increase in daily welding output, allowing the company to complete projects in a fraction of the time previously required."

Lepol