The following is an excerpt originally published on Business News Australia

There is currently an acute shortage of skilled welders required to meet the demand for pipe welding needed to build the world’s essential infrastructure, from the construction of data centres and ships to hospitals and LNG plants.

This workforce challenge, combined with supply-chain management difficulties, has resulted in a near-term challenge in Australia and around the world.

Escalating costs and delays have also created massive bottlenecks in the construction of industrial plants necessary to meet the needs of developed and developing economies worldwide.

To complicate this extremely challenging situation, pipe fabrication shops serving global industries require highly skilled welders.

“Australia is facing a critical demand for welders, and the magnitude of the problem demands a solution. If it’s not dealt with, it’s going to slow industry development,” says Novarc Technologies CEO Soroush Karimzadeh.

“And in this very competitive climate, if you’re not improving productivity, and doing it profitably, winning projects will become more difficult.”

Weld Australia CEO Geoff Crittenden also feels the situation is incredibly demanding. With an ageing welder workforce, and a lack of uptake in the welder trade, Crittenden predicts the Australian industry will have a shortage of up to 70,000 welders by 2030.

“Coupled with the rise of projects on the horizon in a competitive landscape, winning tenders has never been more difficult,” says Novarc Australia senior account executive Brad Walsh.

But there is a solution.

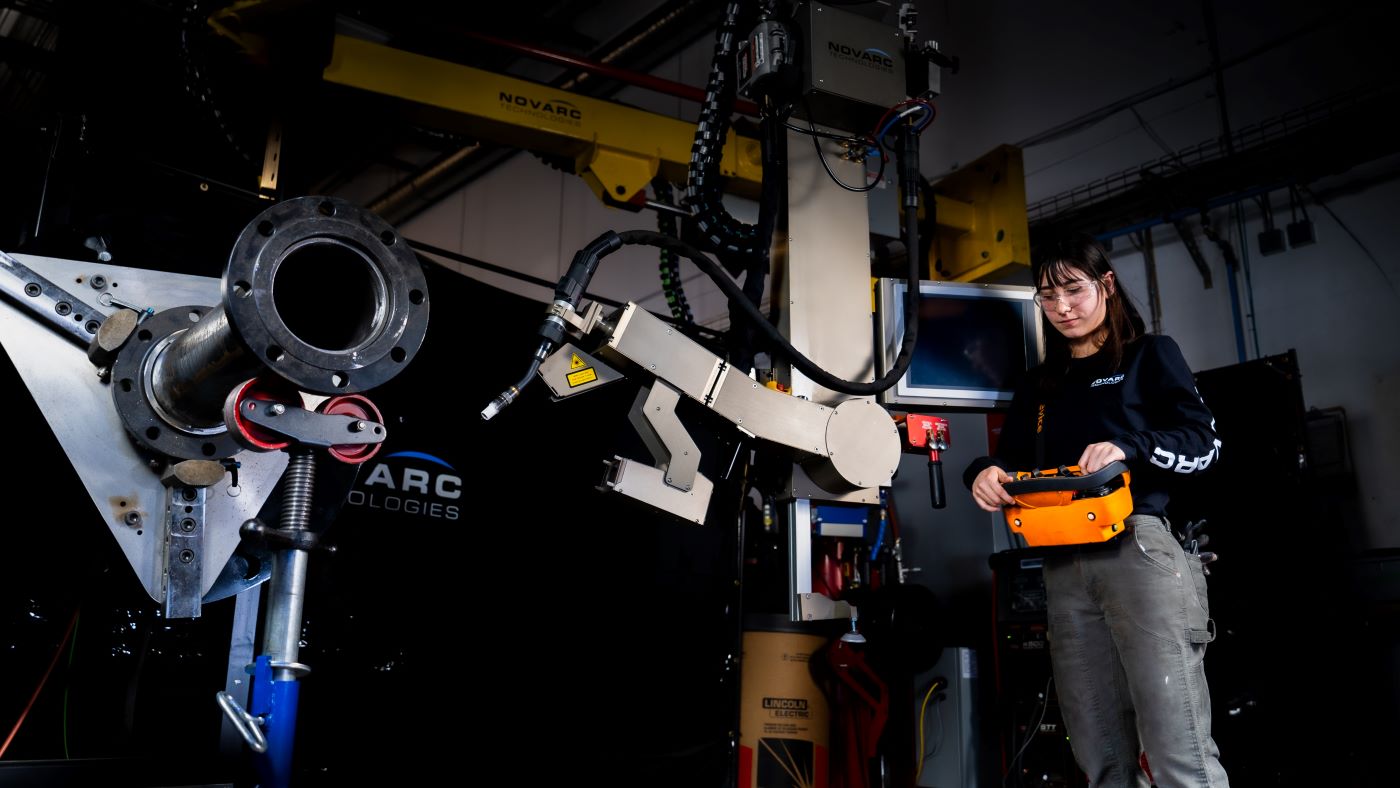

Introducing Novarc’s Spool Welding Robot

Novarc’s Spool Welding Robot (SWR™), currently sold in North America, Europe and the Middle East, is now available across Australia, with clients in Western Australia, Victoria and Queensland.

The consistent message Novarc receives from these markets is “qualified welders are hard to find”.

As the world’s first collaborative welding robot, Novarc’s SWR not only provides the country’s pipe fabrication shops with a solution to the welding labour shortage, it also transforms the way fabrication shops can bid on jobs.

Novarc automates the pipe welding process, working alongside a human operator, to increase productivity, weld quality, consistency and profitability. As a result, Novarc clients often recover their capital investment within six to 18 months.

Novarc’s SWR provides an automation solution to industries such as oil & gas, mining, construction (which includes mechanical contractors), and shipbuilding.

All of these industries are suffering from the same inherent problems today in the fabrication world – the lack of skilled labour and the limited productivity of manual labour. The SWR provides a solution to both of these pain points, with the added benefit of improved working conditions for welders.

Just this month, Novarc announced a significant development that fully automates the welding process. The SWR is now armed with game changing software developed using the company’s years of machine learning. It is embedded in the control system of the SWR and controls the weld in exactly the same way as a human welder would, allowing the boring, repetitive welds to be delegated to the robot.

Called NovEye™ Autonomy (Gen 2), this image processing system integrates state-of-the-art AI algorithms with advanced robotic controls to fully automate the pipe welding process, delivering high quality welds with zero operator intervention, maximising productivity and eliminating errors.

“NovEye Autonomy is the only AI machine learning real-time vision processing system that constantly improves welds based on data collection and model enhancement,” says Walsh.

“Now, a welder can have advanced, real-time control, due to NovEye Autonomy’s sophisticated AI, and powerful hardware. The difference is that a human welder ‘could’ perform a perfect weld, but NovEye does it perfectly.”

How it works is that NovEye Autonomy utilises live-stream video from the camera mounted on the SWR’s torch to analyse the scene and detect welding states. Based on these detected states, the AI adjusts welding and motion parameters in real-time.